The Make-or-Break Detail: How Aluminum Wood Veneer Jointing Defines Project Quality

At the handover of an aluminum wood veneer project, where does an experienced client or designer look first?

Not at how flat the panels are or how beautiful the grain looks—those are the basics.

Their eyes go straight to the joints.

A uniform, razor-straight, seamless joint is the silent declaration of supreme craftsmanship.

A joint that is uneven, with peeling edges or mismatched patterns, instantly downgrades the project, exposing all the underlying sloppy management and technical shortcomings.

Today, let's dissect this most easily overlooked, yet most defining devil-in-the-details.

1. The Joint: Far More Than a "Gap"—It's the Final Test of a System

Many think a joint is just the natural result of two panels meeting. That's completely wrong.

It is, in fact, the final report card for the precise collaboration of four key stages: material, design, fabrication, and installation.

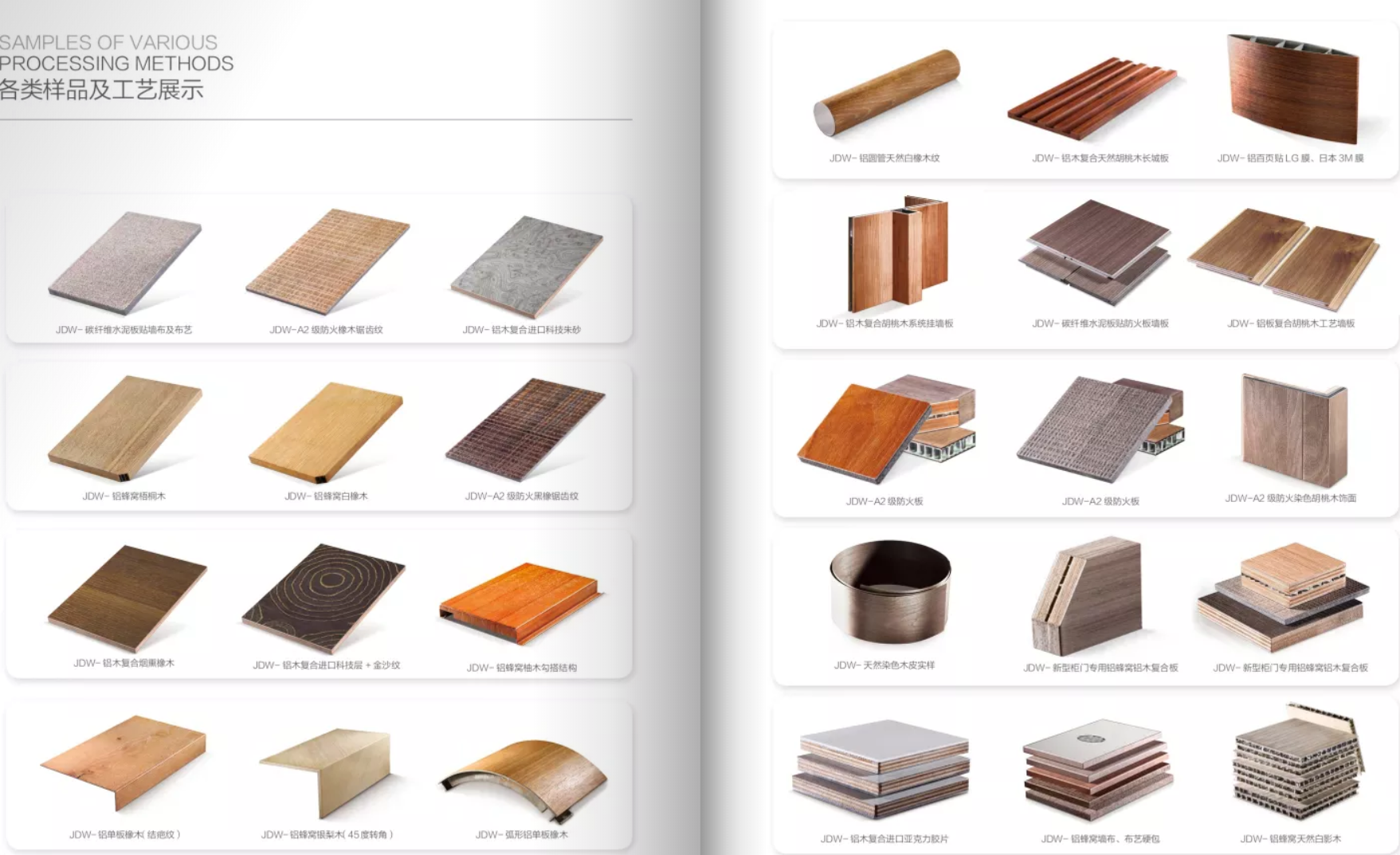

Material is the Foundation: The flatness of the panel, the precision of the cut edges, and the coating's adhesion after cutting are the innate DNA.

Design is the Blueprint: The specified joint width (e.g., 3mm, 5mm), whether tight seams are required, and the pattern alignment (staggered or grain-matching) set the "constitution" for construction.

Fabrication is the Guarantee: The accuracy of CNC folding, the edge coating protection (against chipping), and the positioning of backing frames and bracket systems determine the installation's margin for error.

Installation is the Final Touch: The skill of the installers, the quality of the leveling system, and adaptation to on-site temperature/humidity determine the final outcome.

A millimeter-level deviation in any single stage results in a kilometer-level mistake at the joint.

2. The Three Realms of Joint Quality: Which One Are You In?

Realm 1: Form Without Soul (Barely Passing)

A gap exists and is mostly straight, but problems abound upon closer look:

"Burrs" & "Coating Chips": Improper cutting tools or techniques cause the coating to tear at the aluminum edge, revealing the glaring metal base.

"Step Difference": Adjacent panels are not coplanar, creating a palpable height difference and ugly shadow lines under light.

"Dirt Traps": The joint interior is untreated, becoming a channel for dust and moisture, eventually turning into a blackened seam.

Realm 2: Neat & Clean (Good Standard)

This is the common standard for quality projects today:

Precision Cutting: Using CNC laser or high-precision saw cutting for smooth, burr-free edges.

Systematic Installation: Utilizing specialized brackets with 3D adjustability for precise leveling, ensuring flush panels.

Joint Treatment: Filling with specialized gaskets or sealants color-matched or coordinated with the panel face for visual unity and functional sealing.

Realm 3: Seamless Perfection (The Pinnacle)

This is the craftsmanship that defines "top-tier quality," pursuing visual "invisibility" and physical "perfection":

"Grain-Matching" Joints: This isn't random placement. For panels with continuous wood or stone grain patterns, digital templating is done before fabrication to ensure patterns flow naturally across panels, making the joint part of the pattern, not an interruption.

"Micro-Bevel" or "Shadow Gap" Technique: Creating a minimal bevel (e.g., 0.5mm x 45°) on the panel edge. This tiny斜面 creates a consistent, fine shadow line under light, enhancing the panel's dimensionality and refinement while perfectly masking minor installation tolerances.

"Structural Tight Seam": In some interior applications, using special clip or adhesive systems to achieve a nearly invisible seam. This demands peak requirements for panel flatness, fabrication precision, and installation skill.

3. Heartfelt Advice for Decision-Makers: How to Guard This "Joint" Quality Line?

Define it Early, at the Design Stage: Don't just specify "aluminum wood veneer." The project specifications must clearly state joint width, treatment technique (grain-matching, beveling), and acceptance criteria (flatness, allowable step difference).

Demand to See a Sample Section During Evaluation: Require the supplier to provide a physical sample section, at least 1 meter long, with a complete joint. Feel it with your hand, measure it, shine a light across it—every flaw will be exposed.

Ask the Right Questions:

"How is the coating protected on the cut edges of your panels?"

"Do you provide a compatible leveling bracket system? What is its adjustment precision?"

"What is your detailed design process for achieving grain-matching joints?"

Prioritize "Methodology" Training: The best materials are wasted on unprofessional installers. Ensure your construction team receives specialized installation training from the supplier.

Conclusion

In high-end projects, we never sell just "panels." We sell a certain, flawless final result.

The joint is the most honest and苛刻的 judge of that result. It tests not the quality of a single panel, but the end-to-end systemic capability of a team, from manufacturing to service.

The so-called top tier is about turning every detail others might overlook into an insurmountable barrier.

Call to Engagement:

In your experience, what project cases have "achieved legend" or "crashed and burned" due to joint treatment? Or, what technical questions do you have about pursuing极致 tight-seam or grain-matching techniques?

Please share and discuss in the comments. Let's pool our knowledge.