Application Guide: Aluminum-Wood Veneer for High-Humidity & Demanding Commercial Spaces

In high-end commercial design, creating atmosphere is as crucial as material durability. But when a project is located in coastal areas, near spas, restaurant kitchens, or any space with high humidity, heavy traffic, and stringent maintenance requirements, the palette of classic materials suddenly feels limiting.

Solid wood warps. Stone feels cold and can harbor mold. Standard panels often lack the depth for luxury. What is the solution?

This guide explores how Aluminum-Wood Veneer Composite Panels are becoming the ultimate specification for these demanding scenarios, providing a practical reference from design and technology to selection.

Part 1: Why Traditional Materials "Fail" in High-Humidity Commercial Spaces

Solid Wood / Wood Veneer on Non-Moisture Stable Substrates: Prone to expansion, contraction, cracking, and warping due to moisture absorption. High humidity encourages mold and mildew growth, leading to very high maintenance costs.

Painted/Stained Surfaces: In environments with high humidity fluctuations, finishes can blister, peel, and are difficult to repair locally.

Standard MDF/Plywood: Core materials swell significantly when exposed to moisture, causing edge-raising and delamination. The risk of VOC off-gassing may also increase.

The Core Problem: Warping, Mold, Difficult Maintenance, Short Lifespan—issues that directly compromise space quality and operational budgets.

Part 2: The Core Advantages of Aluminum-Wood Veneer: Mitigating Four Key Risks

The composite structure of an aluminum core bonded to a natural wood veneer solves these problems fundamentally:

Superior Moisture Resistance & Dimensional Stability (Solves: Warping)

Principle: The aluminum alloy core (typically corrosion-resistant series 3 or 5) is completely impermeable, creating a barrier that isolates the wood veneer from moisture.

Data: Under controlled conditions (e.g., 23°C, 50% RH), its linear thermal expansion coefficient is approximately 2.3×10⁻⁵ /°C, with deformation rates typically below 0.3%, matching the stability of metal itself.

Ideal For: SPA changing rooms, indoor pool surrounds, feature walls in seafood restaurants, hotel bathroom dry areas.

Class A Fire Safety (Solves: Safety Compliance)

Principle: The aluminum core is non-combustible, and the composite core materials and adhesives are specially treated.

Standard: The full composite panel can achieve Class A (ASTM E84) / Euroclass B-s1, d0 or A2-s1, d0 fire ratings, meeting the strictest codes for most commercial spaces.

Ideal For: Hotel lobbies, conference rooms, corridors adjacent to commercial kitchens, and public building thoroughfares.

Easy Cleaning & Low Maintenance (Solves: Operational Burden)

Principle: The surface is protected by a high-performance UV-cured or polyester coating, creating a dense, seamless shield.

In Practice: Most stains wipe clean with a damp cloth. The panels resist chemicals, UV yellowing, and fading. Localized wear can be professionally refinished, ensuring long-term value.

Ideal For: Luxury retail walls, hotel front desks, healthcare facility corridors, university libraries—any high-traffic area requiring frequent cleaning.

Sustainability & Authentic Design (Solves: Aesthetic & Ethical Compromise)

Principle: Uses ultra-thin slices of precious wood veneer (typically 0.3-0.6mm), increasing yield from a single log by up to 40 times. The aluminum core is 100% recyclable.

Result: Retains the authentic grain, tactile warmth, and light-catching variance of natural wood—far from a printed imitation. Contributes to LEED, BREEAM, or WELL building certification points.

Ideal For: Any project pursuing high-end, biophilic design with a strong focus on corporate social responsibility.

Part 3: Key Specification & Design Guidelines

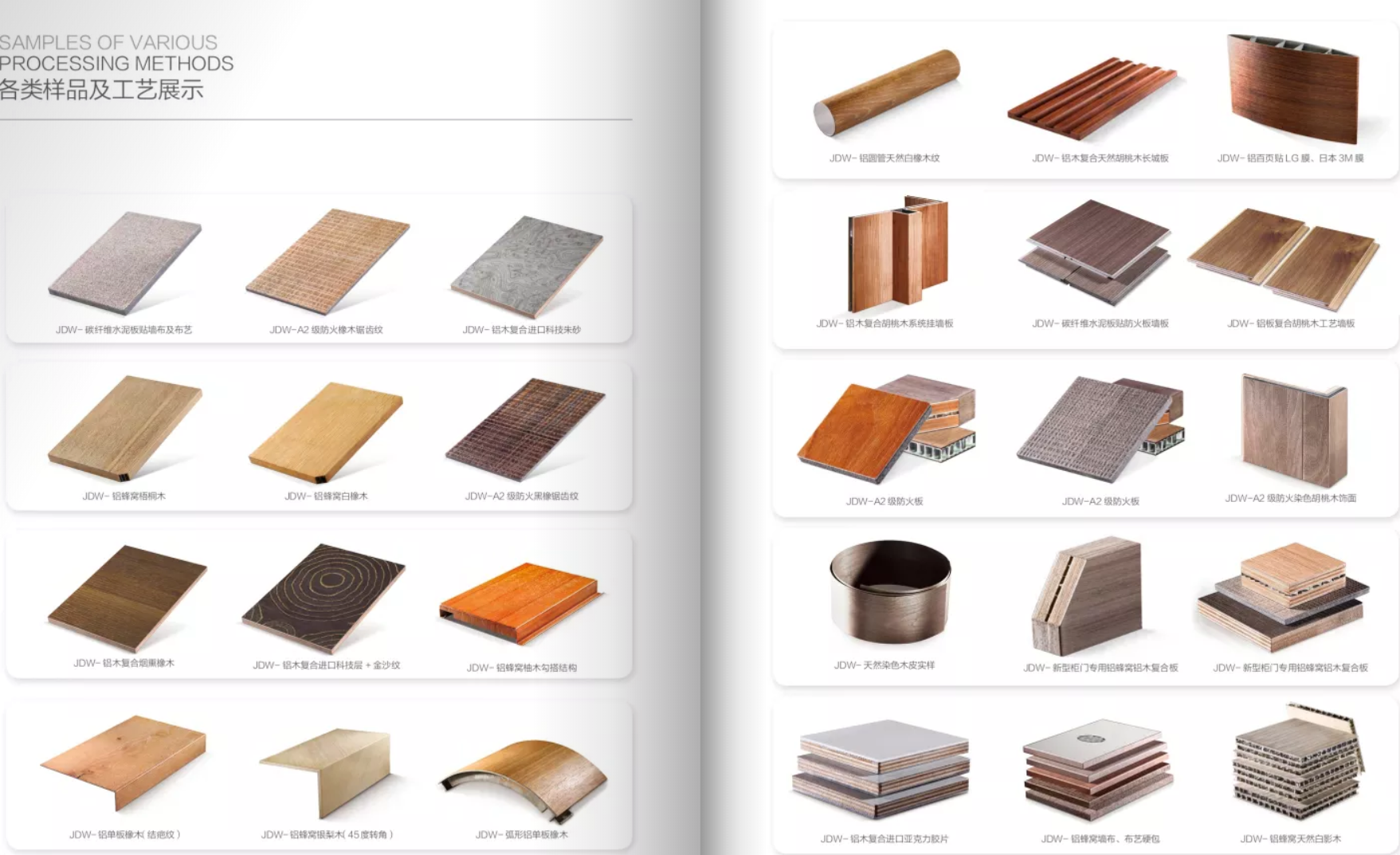

Veneer Selection:

For Stability: Prioritize species like Oak, Walnut, Teak, or Ash.

For Style: Dark grains (e.g., Ebony Stain) convey luxury and depth; light grains (e.g., White Oak) achieve a bright, contemporary feel.

Finish: Choose from open-pore (for natural texture), smooth-pore (for easier cleaning), or special effects like brushed or wire-brushed.

Thickness & Format:

Common Total Thickness: 3mm, 4mm, 5mm. Determined by substrate flatness and installation method (adhesive or mechanical).

Pro Tip: For large feature walls, specify larger panel sizes (e.g., 5' x 10' / 1500mm x 3000mm) to minimize visible joints.

Recommended Installation Systems:

Adhesive System: Requires a perfectly flat, stable substrate (e.g., leveled concrete, cement board). Must use a specified high-performance structural silicone.

Mechanical/Ventilated Rainscreen System (Highly Recommended): Uses an aluminum substructure to create a drained and ventilated cavity. This is critical for managing condensation and thermal movement, especially in facade or high-moisture interior applications.

Detailing is Key:

Well-designed corner profiles, joint details, and expansion joints are essential for a premium finish. Engage with your supplier early in the design phase.

Part 4: A Brief Case Study Snapshot

Project: Luxury Coastal Resort – Lobby & All-Day Dining

Core Challenge: Salt spray corrosion, high indoor/outdoor humidity differential, need for a warm, natural aesthetic with minimal upkeep.

Solution:

Material: 4mm Teak Veneer aluminum composite panel with a weather-resistant UV topcoat.

Structure: Ventilated rainscreen system allowing continuous air circulation behind the panels.

Result: After five years, the walls maintain their original beauty with zero warping, mold, or corrosion, successfully withstanding the harsh environment while delivering the desired "natural luxury" experience.

Conclusion & Call to Action

Aluminum-wood veneer eliminates the need to compromise between aesthetics and performance. It allows us to apply the warm language of wood to the most demanding chapters of architecture.

This guide is just a starting point. Every project has unique challenges and character.

If you are planning a commercial project facing humidity, fire-rating, or high-traffic challenges, and want to explore how aluminum-wood veneer can work in your specific context, we are here to help with:

Complimentary Samples: Experience the authentic texture and quality.

Technical Support: Direct consultation with your design and construction team.

Custom Solutions: Tailored planning from material selection to installation details, based on your designs.

Feel free to share the material challenges you've faced in demanding projects in the comments below, or message me directly for more detailed technical documentation and case studies.