How to Choose the Perfect Aluminum Veneer Thickness and Wood Grain for Your Project

Choosing the wrong material can undermine even the best design.

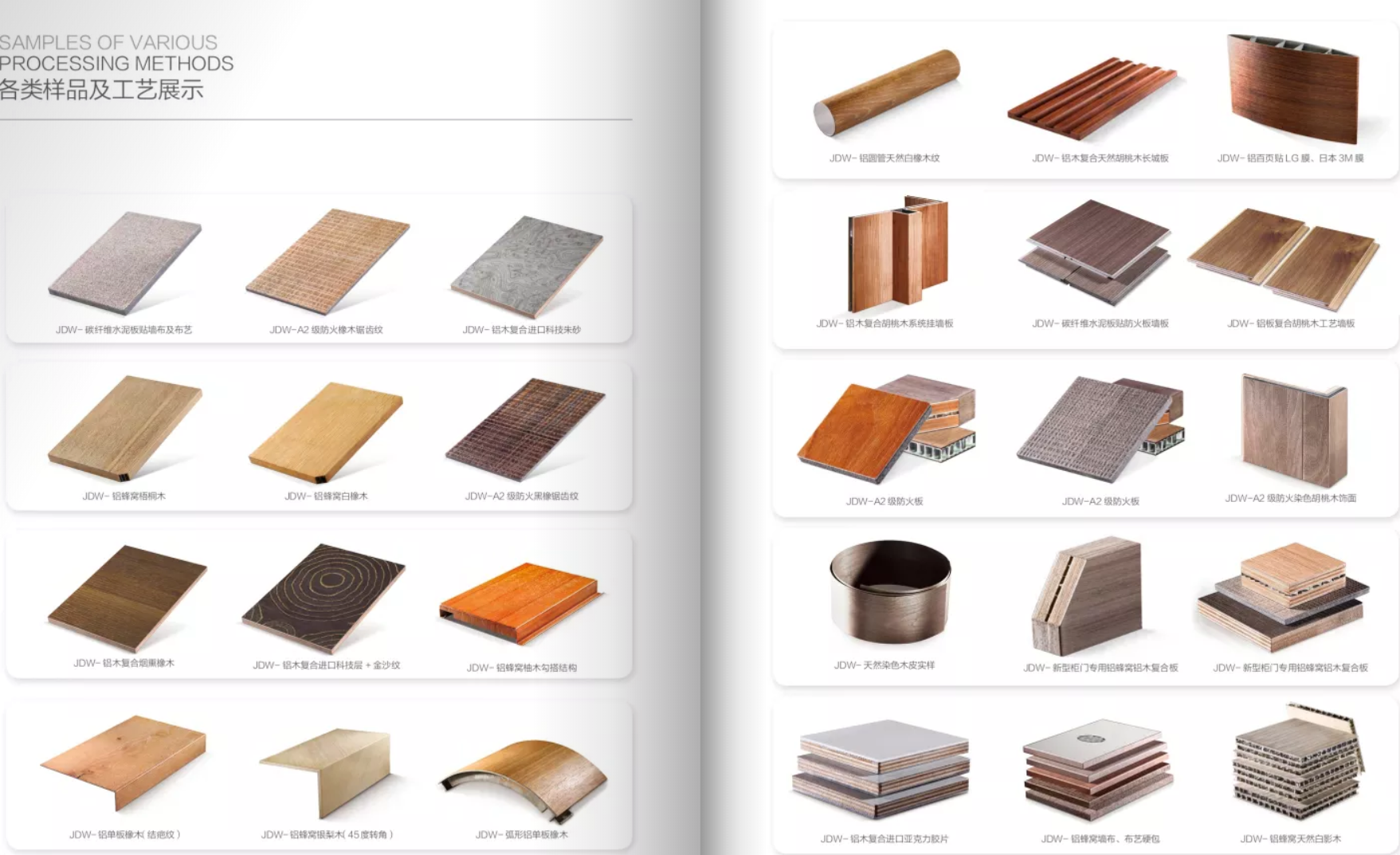

When an architect requests "a warm wood-like texture for the exterior wall that can withstand coastal salt spray," when an interior designer wants "a smooth, curved wood-grain effect on the ceiling," or when a furniture brand seeks "a lightweight yet strong wood veneer finish"—aluminum veneer becomes the ideal choice due to its unique combination of properties.

But how do you find the most suitable option among the various parameters? This article will delve into the core dimensions of aluminum veneer selection: Thickness and Wood Grain, helping you make precise decisions.

01 Thickness Selection: More Than Just a Trade-off Between Thin and Thick

The thickness of aluminum veneer is not arbitrary; it directly impacts material performance, processing possibilities, and final cost. Mainstream thicknesses in the market typically range from 0.7mm to 3.0mm. How do you decide?

Architectural Facade Applications: This is the most demanding scenario for materials. Outdoor environments require continuous resistance to UV rays, temperature fluctuations, wind loads, and potential physical impact.

Choosing a thicker specification of 2.0mm-3.0mm is standard practice. A thicker aluminum substrate provides greater structural rigidity, ensuring flatness during installation of large panels and resisting deformation from wind pressure.

In areas prone to typhoons or for high-rise buildings, thickness must take precedence over aesthetics, and specialized structural calculations with curtain wall consultants may even be necessary.

Interior Walls and Ceilings: Here, design freedom is greater, but effect and safety must be balanced.

For large, flat wall surfaces, 1.0mm-1.5mm offers a cost-effective balance, ensuring quality texture while remaining easy to handle and install.

For unique curved or custom shapes (such as wavy ceilings or arched corners), thinner sheets of 0.7mm-1.0mm are the only answer. Their excellent flexibility allows for complex three-dimensional forms with specialized adhesives—something traditional solid wood or wood veneer panels cannot achieve.

Furniture and Detail Finishes: These applications prioritize material refinement and processing precision.

For cabinet doors, tabletop edges, or decorative trim, ultra-thin specifications of 0.5mm-1.0mm are most common.

They provide a perfect wood-grain finish for substrates (like MDF or metal frames) while minimizing overall weight and thickness.

Core Principle: Purpose determines strength, shape determines flexibility. Clearly defining the application scenario and design form early in the project quickly narrows down the thickness options.

02 Wood Grain Aesthetics: From Natural Expression to Design Language

The wood grain is the soul of aluminum veneer. Choosing it goes far beyond "which wood looks good"; it's about communicating design intent and shaping spatial mood.

Wood Species & Style: Each Texture Has Its Own Character

Straight-Grain Oak, Maple: Clear, uniform, and flowing grain conveys a modern, minimalist, and rational atmosphere—ideal for minimalist and Japanese-style designs.

Crotch / Quarter-Sawn Walnut, Teak: Grain with significant variation, prominent cathedral patterns or mineral streaks, inherently narrative—perfect for creating rich, luxurious, naturalistic spaces.

Smoked, Dark-Treated Veneers: Like charred oak, where processes enhance the dramatic contrast of the grain, suitable for personalized, industrial, or high-end commercial settings.

Surface Treatment: The Interplay of Touch and Light

Open-Pore Finish: The wood pores (grain grooves) are not completely filled, leaving a distinct tactile, three-dimensional texture. It maximizes the raw, natural feel of wood.

Closed-Pore / Smooth Finish: The surface is smooth and even, like glass, easy to clean and maintain. The visual wood grain remains clear, but the touch is uniform, appearing more refined and modern.

Matte, Gloss, Velvet: Different sheen levels completely alter the character of the same wood grain. Matte is sophisticated and understated, gloss is fashionable and eye-catching—considerations must align with the overall lighting design of the space.

Matching Principle: Large spaces look at style, small details look at texture. Macroscopically, the wood grain style should align with the architectural or interior design theme. Microscopically, the surface treatment must consider frequency of touch and cleaning requirements.

03 Decision Matrix: When Thickness Meets Wood Grain

The real challenge lies in the intersection of thickness and wood grain—they constrain yet complement each other.

Large Curved Outdoor Curtain Wall → This is a point of contradiction. Curves require thin (0.8-1.2mm), but outdoors demands durability. The solution: Choose an ultra-flexible thin gauge, but ensure its surface coating is a top-grade outdoor weather-resistant fluorocarbon paint. For wood grain, avoid overly complex cathedral patterns, as high curvature may distort the texture excessively; uniformly grained straight patterns are preferable.

Hotel Lobby Feature Wall → This is the material's "stage." A thickness of around 1.5mm ensures flatness like stone. For wood grain, boldly use exotic species with dramatic cathedral figures, paired with an open-pore matte finish, creating subtle light and shadow plays under lighting to showcase luxury quality.

Hospital/School Corridor Walls → Function first. Requires impact resistance and easy cleaning. Recommend a thickness of 1.2mm or above for enhanced durability, with a closed-pore matte finish. Wood grain should be gentle and calming, like mild maple or white oak, to create a soothing environment.

A Quick Reference Table:

| Application Scenario | Recommended Thickness | Wood Grain & Finish Recommendation | Primary Consideration |

|---|---|---|---|

| High-rise Building Facade | 2.0mm - 3.0mm | Straight/Uniform Grain; Outdoor Fluorocarbon Paint, Matte | Structural Safety, Weather Resistance |

| Special-Shaped Building Skin | 0.7mm - 1.2mm | Simple Grain; Pre-coated Outdoor Paint | Bending Performance, Form Realization |

| Interior Large Wall Surface | 1.0mm - 1.5mm | As per Design Style; Open or Closed Pore Finish | Flatness, Visual Effect |

| Curved Ceiling/Feature | 0.7mm - 1.0mm | Straight Grain Preferred; Flexible Specialty Coating | Bendability, Adhesive Application Technique |

| High-end Furniture Finish | 0.5mm - 1.0mm | Exotic Wood Grain; High-Tactility Surface Finish | Refinement, Processing Precision |

| High-Traffic Areas | 1.2mm+ | Moderate Grain; Closed-Pore, Wear-Resistant Finish | Durability, Ease of Maintenance |

04 Final Advice: Request Samples and Conduct Tests

Selecting on drawings is just the first step; decision by physical sample is essential.

Request Full-Size Samples: Observe sample boards of different thicknesses and wood grains side-by-side under the project's expected lighting conditions (natural, warm, cool light) to assess color and texture variations.

Perform Simulation Tests: For critical applications, request small samples from suppliers for scratch resistance, UV aging, or bending tests.

Confirm Supply Chain: Ensure the chosen specification and grain pattern have stable inventory and lead times to avoid mid-project substitutions.

Selecting aluminum veneer is a fusion of rational engineering and aesthetic sensibility. The precise thickness ensures it stands the test of time, while the appropriate grain makes an instant emotional impact. The next time you face a specification decision, may this guide help you find the optimal solution.

**The truly suitable material will quietly integrate into the design, silently endure the passage of time, and ultimately be perceived by all.

The truly suitable material will quietly integrate into the design, silently endure the passage of time, and ultimately be perceived by all.