Aluminum Honeycomb Wood Veneer: The Invisible Ally for Architects, Balancing Aesthetics and Safety

Have you ever faced this "impossible trinity" in a high-end design project?

The Client demands: The warm, textured feel and premium look of natural wood grain.

The Designer envisions: Large spans, curved surfaces, and complex forms that must not warp after installation.

The Building Code mandates: Compliance with strict fire safety standards, often requiring a Class A fire rating.

This was a classic dilemma forcing countless compromises—until Aluminum Honeycomb Wood Veneer emerged as the "invisible ally" that breaks this deadlock. It is not merely a decorative material but a comprehensive systemic solution for both aesthetics and engineering.

1. Deconstructing the Core: Why is it the "Deceptively Strong" Performance Leader?

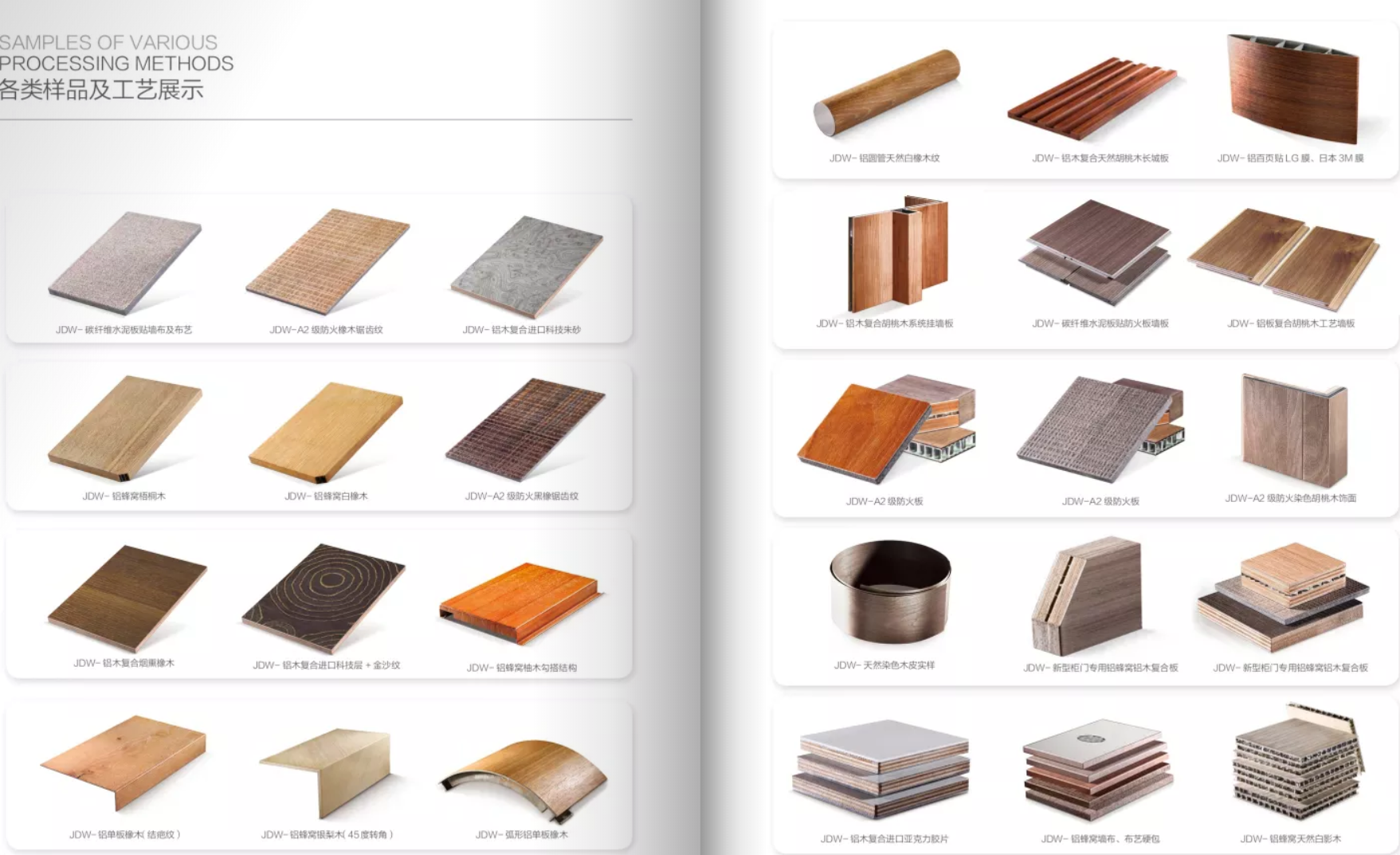

The exceptional performance of aluminum honeycomb wood veneer stems from its unique composite "sandwich" structure:

Surface Layer (The Aesthetic Face): High-grade natural wood veneer or premium reconstituted wood veneer provides an authentic, irreplaceable grain texture and tactile quality.

Core Layer (The Powerhouse): Aerospace-grade aluminum honeycomb core. This is the material's "soul," giving the panel an exceptional strength-to-weight ratio—it offers remarkable flatness while being up to two-thirds lighter than a solid wood panel of the same size, yet boasts impressive flexural and impact strength.

Backing Layer (The Stabilizing Base): A high-strength aluminum sheet or fire-resistant backer works synergistically with the honeycomb core to ensure outstanding dimensional stability in any temperature or humidity environment.

What is the direct benefit of this structure?

Simply put: It liberates wood veneer from its "fragile" stereotype, allowing it to be used in applications traditionally deemed unsuitable for wood—whether it's a multi-story hotel lobby feature wall, a high-humidity spa, or public building corridors with stringent fire safety requirements.

2. Three Key Value Propositions: Addressing the Pain Points of Key Decision-Makers

For different stakeholders in a project, aluminum honeycomb wood veneer offers compelling value:

| Stakeholder | Primary Concerns | Value Delivered by Aluminum Honeycomb Wood Veneer |

|---|---|---|

| Client / Developer | Cost control, timeline, long-term maintenance, asset value | 1. Lower Total Cost of Ownership: Fast installation (dry-hanging systems can reduce on-site time by over 40%), near-zero maintenance, and clear life-cycle cost advantages. 2. Minimized Risk: Eliminates warping, cracking, and the associated costly call-backs and brand reputation damage. |

| Architect / Designer | Design freedom, faithful execution of vision, material innovation | 1. Unprecedented Form Freedom: Enables complex designs like curves, double curves, and seamless large-format panels, bringing even the most ambitious concepts to life. 2. Superior Aesthetic Outcome: Accepts any wood finishing technique (staining, wire-brushing, fuming, etc.) while ensuring flawless large-panel visuals. |

| General Contractor / Fire Consultant | Construction safety, code compliance, project predictability | 1. Inherent Safety: Can achieve up to Class A2 fire ratings, fundamentally removing the fire hazard associated with traditional wood. 2. Construction-Friendly: High degree of factory prefabrication allows for standardized, predictable on-site installation with controlled quality and schedule. |

3. Application Revolution: Where It's Redefining the Rules

This material is transforming expectations in premium spaces:

Commercial Spaces (Luxury Hotels, Flagship Retail):

Challenge: A hotel lobby required a 20-meter-long, 6-meter-high curved feature wall with a wood finish, located directly under an HVAC vent with fluctuating humidity.

Solution: Pre-curved aluminum honeycomb wood veneer panels were factory-fabricated and installed on-site using a modular dry-hanging system. The wall perfectly achieved the specified teak grain and curvature. After three years of use, the surface remains perfectly flat with no warping or visible seam separation.Transportation Hubs (Airports, High-Speed Rail Stations):

Challenge: An airport lounge needed the warm ambiance of wood but had to meet the strictest fire ratings and withstand high abrasion and impact.

Solution: Aluminum honeycomb panels with a high-performance wear-resistant coating were specified. Their Class A fire performance passed inspection seamlessly, and the honeycomb structure's high impact resistance handles occasional luggage contact, maintaining its appearance over time.Healthcare & Education (Hospitals, Labs, Schools):

Challenge: A hospital ward required a warm, healing environment but needed a hygienic, easy-to-clean, and absolutely fire-safe solution.

Solution: Panels with an antibacterial coating were used, installed with sealed seams to create a continuous, monolithic surface that is easy to clean and disinfect, all while meeting stringent healthcare fire codes.

4. Selection Guide: How to Identify a True "High-Performance Ally"?

With varying product quality on the market, focus on these four critical aspects:

Inspect the Core (Literally): Request a sample and examine the honeycomb core cross-section. A high-quality core will have uniform cell size, orderly alignment, and sufficient foil thickness (typically not less than 0.07mm), with perfect adhesion to the face and back sheets.

Demand Performance Data: Require official test reports from accredited laboratories, covering at minimum: fire rating (Class A2 is optimal), formaldehyde emissions (E0 or better), flexural strength, and resistance to humidity cycling.

Verify with Past Projects: Assess the supplier's portfolio for complex, completed projects similar to yours. A site visit to a project completed 2-3 years prior is ideal to evaluate long-term performance.

Evaluate the Support System: A superior supplier provides not just panels but a complete solution encompassing design collaboration, technical support, and installation guidance.

Aluminum Honeycomb Wood Veneer solves far more than just a finishing problem.

It resolves the conflict between beauty and safety, bridges the gap between vision and reality, and settles the debate between initial cost and long-term value. Behind every project that specifies it lies a rational pursuit of higher standards, more predictable outcomes, and enduring quality.

It may not be the default choice for every project, but it is undoubtedly the most reliable "invisible ally" for high-end projects that refuse to compromise and strive for excellence.

Let's Discuss:

In your projects, have you ever had to compromise a design due to material limitations? Regarding the "versatile" performance of aluminum honeycomb wood veneer, what is your biggest question or skepticism? Share your thoughts or challenges in the comments below.