Embrace the Future: Why Aluminum-Wood Veneer Composites are Redefining High-End Design and Architecture?

Driven by the dual forces of sustainable development and the demand for high performance, the field of building materials is undergoing a quiet revolution. If you are in architectural design, high-end furniture manufacturing, marine interiors, or project development, you have likely felt the market's increasingly stringent demands for materials: they must possess the aesthetic texture of natural materials while being able to withstand challenges like humidity, corrosion, and fire; they need to be lightweight to reduce structural load, yet strong and durable to ensure long-term value.

Traditional solid wood, while warm and natural, has shortcomings in stability, fire resistance, and durability. Single-metal materials, on the other hand, struggle to meet the pursuit of aesthetics and tactile experience. Today, an innovative solution is bridging this gap. It not only perfectly balances these seemingly contradictory needs but also unlocks unprecedented design possibilities—this is the Aluminum-Wood Veneer Composite.

Demystifying Aluminum-Wood Veneer: Not a Simple "Veneer," but a Fusion of Technology and Nature

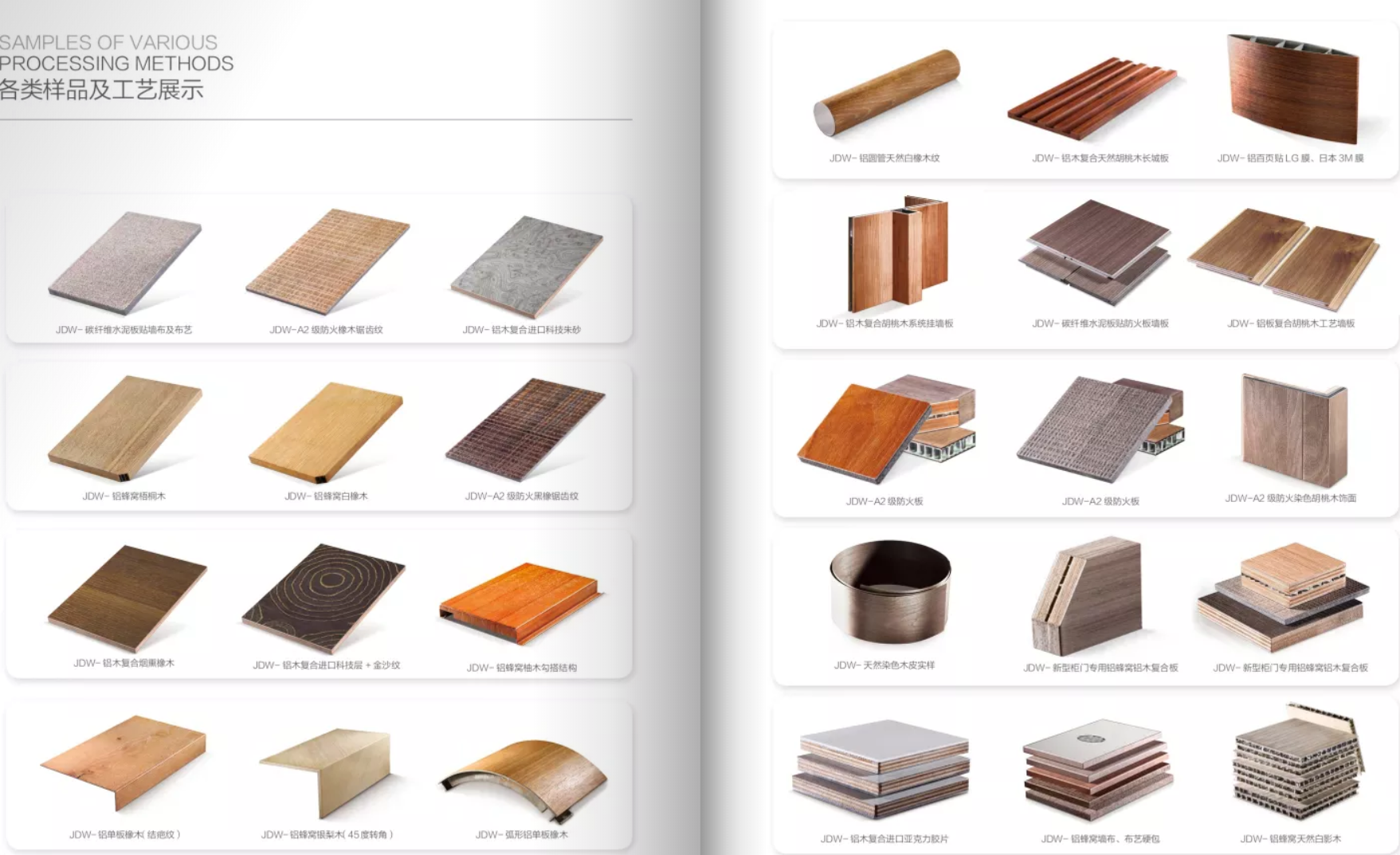

The Aluminum-Wood Veneer Composite, often a type of aluminum composite panel, features an innovative "sandwich" core structure:

Stable Core Material: Typically, a high-strength aluminum alloy sheet or aluminum honeycomb core is used. The aluminum honeycomb core mimics the hexagonal structure of a natural honeycomb, achieving extremely high compressive and flexural strength with minimal weight.

Natural Surface Layer: A layer of carefully selected natural wood veneer, engineered wood veneer, or stone, fabric-patterned finishes is bonded onto the stable aluminum substrate through advanced lamination technology. This veneer is not merely decorative; it is firmly integrated with the core material, ensuring authentic wood grain texture and visual effect.

This combination is not a simple physical overlay but involves precise thermal bonding or adhesive processes that firmly join two materials with different polarities (polar wood and non-polar aluminum), resulting in a new type of decorative material with comprehensively upgraded performance.

Unparalleled Performance Advantages: Solving Core Pain Points in High-End Projects

The Aluminum-Wood Veneer Composite has rapidly secured a place in the high-end market by precisely addressing long-standing pain points across multiple industries.

1. Ultimate Stability, Free from Deformation Woes

Whether in dry or humid environments, solid wood is prone to expansion, contraction, or even cracking due to moisture changes. Aluminum-Wood Veneer Composite completely solves this issue. Aluminum itself has high thermal conductivity, maintaining overall stability in hot and cold environments. The honeycomb structure evenly distributes stress, ensuring that even large panels maintain extremely high flatness without warping. This allows designers to confidently use large-format panels without worrying about future sagging or deformation, particularly suitable for demanding applications like luxury yacht cabins and high-end hotel lobby walls.

2. Light as a Feather, Strong as a Rock

Material lightweighting is a key pursuit in modern construction and transportation. Aluminum-Wood Veneer Composite is extremely light, weighing only about 1/5 of solid wood and 1/6 of glass of the same volume. This significantly reduces building structural loads and simplifies transportation and installation, making it especially suitable for vehicle interiors, aviation interiors, and facade renovations of existing buildings. Despite its lightness, its specific strength (strength-to-weight ratio) surpasses many traditional materials, ensuring safety and durability.

3. Fearless in Harsh Environments, Extending Service Life

Traditional wood materials are highly susceptible to damage in damp, high-salinity environments like bathrooms, kitchens, coastal areas, or basements. Aluminum-Wood Veneer Composite demonstrates exceptional waterproofing, moisture resistance, corrosion resistance, and weather resistance. The surface aluminum layer and dense composite layer effectively block moisture ingress, making it perfect for outdoor facades, seaside villas, high-end kitchen/bath spaces, and medical cleanrooms, greatly reducing maintenance costs and replacement frequency.

4. Safe and Eco-Friendly, Demonstrating Responsibility and Foresight

Safety and sustainability are core to today's procurement decisions. Aluminum-Wood Veneer Composite offers excellent flame retardancy. The aluminum substrate itself is non-combustible, enhancing safety at the source. Additionally, it contains no harmful volatiles like formaldehyde, and its production process is more environmentally friendly. Crucially, aluminum is one of the most recycled materials on Earth (with a recycling rate of up to 98% for building aluminum), enabling nearly complete resource circularity. It is an ideal choice for green building and sustainable projects.

Application Scenarios: From Imagination to Infinite Possibilities

The performance advantages of Aluminum-Wood Veneer Composite are expanding its applications from traditional areas to more cutting-edge scenarios:

Architecture & Facades: Creating lightweight, flat, weather-resistant modern building exteriors, or used in interior spaces like grand lobbies and airport terminals that require both grandeur and detail.

High-End Transportation Interiors: Widely used in cruise ship cabins, private yachts, luxury RVs, and business jet cabins for interior decoration, meeting lightweight and fire safety regulations while creating a luxurious, warm ambiance.

Top-Tier Furniture & Interior Decoration: Used for high-end custom cabinets (especially for wet areas like bathroom and kitchen cabinets), system furniture, wall panels, and art installations, bringing natural wood grain beauty into modern living spaces.

Specialized Fields: Providing reliable solutions for laboratories, hospitals, data centers, and other places with special requirements for cleanliness, stability, and fire safety.

To Decision-Makers and Innovators: How to Take the First Step in Collaboration?

Recognizing the potential of Aluminum-Wood Veneer Composite is just the first step. For architects, designers, manufacturers, and project procurement managers, choosing the right supplier and launching a successful project requires deeper consideration. The following key steps and checklist can provide a clear action path:

1. Precisely Define Your Project Needs

Before inquiring, clarify the following with your team. This will help potential suppliers offer the most suitable solutions:

Core Performance Priorities: What is the biggest challenge for your project? Extreme weather resistance, strict fire ratings, ultra-high flatness requirements, or ultimate lightweighting?

Aesthetic & Craftsmanship Details: What type of finish do you prefer? (e.g., natural veneer of a specific wood species, stained veneer, or engineered veneer with special textures?) Any specific requirements for surface treatment (like open-pore finish, closed-pore finish, matte, or gloss?)

Specifications & Installation: What are the required panel thickness and dimensions? Where is the project located? What installation system is planned (e.g., hidden brackets, click systems)? This affects production costs and logistics.

2. Ask Potential Suppliers Professional Questions

During initial contact, the following questions can help you quickly assess a supplier's expertise and product reliability:

"For our project environment (e.g., coastal high-salinity area), what specific process guarantees and quality test data do you have regarding the composite panel's bond strength and mid-to-long-term corrosion resistance?"

"Can you provide a physical sample book of different wood veneer finishes? We'd like to feel the texture, color, and touch firsthand."

"For large-format panels, how do you ensure corner protection during transportation and overall flatness after installation? Are there reference cases of similar successful projects?"

"Are the product's environmental certifications (e.g., formaldehyde emissions, recycled content) and fire rating certifications (e.g., Class A) complete? Can you provide the certificates?"

3. Initiate a Small but Crucial Pilot Project

For a first-time collaboration or large project, a wise strategy is:

Propose a small-batch sample order or custom fabrication of a mock-up panel. This allows you to test the material's appearance, workability, and compatibility with other on-site materials in a real-world setting, minimizing decision risk.

Material innovation is the cornerstone of design innovation. Aluminum-Wood Veneer Composite is not just a new material; it represents a smarter, more responsible, and more aesthetically pleasing way of building.

Are you currently seeking a solution for a project facing environmental, weight, or aesthetic challenges? Or are you already planning your next cutting-edge design that fuses nature and technology?

Feel free to share the material challenges in your field in the comments below, or message me directly on LinkedIn. We can discuss how Aluminum-Wood Veneer Composite can offer a practical solution for your specific needs and provide relevant technical documentation and sample support.

(Call to Action)

Follow my LinkedIn account for more in-depth analysis on innovative building materials, sustainable design, and global project cases. Let's build better spaces with superior materials together.