Anti-Cracking Techniques for Double-Curved Aluminum Panels: A Comprehensive Guide

Double-curved aluminum panels, with their smooth and flowing curved surfaces, are an indispensable visual element in modern architectural landmarks. However, the transformation from a flat sheet to a complex surface carries an inherent risk of cracking. This issue not only leads to significant material and labor waste but also directly impacts the final aesthetic expression and structural integrity of the building.

01 Root Causes of Cracking: More Than Just Bending

Understanding cracking during the processing of double-curved aluminum panels requires recognizing that it's not merely a "bending" issue. The sheet undergoes complex three-dimensional stress during plastic deformation.

When tensile deformation exceeds the material's limit, tearing occurs, especially common in biaxial stretching zones. Shear deformation areas, such as the corners of square or box-shaped parts, are also prone to cracking.

Another challenging scenario is "aging cracking" and "surface micro-cracking." The former is related to material state and residual stress; the latter can occur due to processes like excessive thinning during deep drawing or over-peening, leading to fine cracks on the sheet surface.

These micro-cracks are initially hard to detect but significantly affect the material's long-term performance and surface appearance.

02 Material Science: Building "Plastic Genes" for Curves

The first line of defense against cracking begins with the scientific selection and pretreatment of materials.

Common architectural aluminum sheets (such as 3003 aluminum alloy) often lack sufficient elongation. Forcing them into double-curved shapes can easily cause cracking. Professional manufacturers prefer alloys with high elongation rates like 5052 or 5754. They act like "gymnasts among metals," maintaining structural stability after significant deformation.

Advanced production technologies can build "elastic genes" at the micro level.

For example, electromagnetic stirring continuous casting technology can refine the grains of aluminum to 30-50 microns, far below the 100+ microns of traditional processes. This equiaxed grain structure significantly eliminates casting stress concentration, reducing the cracking rate during double-curved forming from 18% to as low as 1.2%.

03 Core Processes: Dual Control of Pressure and Precision

In forming processes, the core of preventing cracking lies in the precise control of pressure and deformation. The blank holder stretch forming method is a key technique.

This method dynamically optimizes variable blank holder force throughout the stretching process, precisely controlling the pressure within a safe window—avoiding wrinkling (too little pressure) and preventing cracking (too much pressure).

The emerging superplastic bulging-hydraulic composite forming technology represents a higher level of process sophistication.

This technology employs a dual-pressure chamber cooperative control system: the upper chamber uses high-pressure nitrogen for rapid bulging, while the lower chamber dynamically adjusts local pressure distribution through hydraulic oil. Iterative optimization based on finite element simulation can reduce sheet thickness reduction from 25% in traditional processes to 12%, greatly enhancing material safety during forming.

For large components, the combined process of preloading and creep age forming shows advantages.

A patented technology developed by Central South University involves pre-pressing large, variable-curvature aluminum sheets using a gantry and an array of loading mechanisms to make them initially conform to the mold. The sheet is then fixed by vacuum suction and finally placed in an autoclave for creep age forming. This process is stable and reliable, avoiding cracking issues caused by difficult-to-control vacuum processes.

04 Digital Technology: Guardian of Millimeter-Level Precision

Modern double-curved aluminum panel processing has entered an era of digital precision control. Five-axis CNC roll bending machines can adjust roller angles with 0.1° precision based on programmed instructions, enabling the forming of complex curved surfaces.

More advanced systems integrate high-precision laser displacement sensors on the mold surface, scanning the aluminum sheet profile at 200 times per second and comparing it in real-time with the theoretical CAD model. When a local curvature deviation exceeding 0.3 mm is detected, the system automatically adjusts the pressure of the corresponding pressure chamber within 0.2 seconds, achieving "forming with inspection, inspection with correction."

This real-time closed-loop control increases the first-pass qualification rate for double-curved aluminum panels from 72% to 95%.

Panels that have undergone preliminary forming require stress relief to prevent subsequent cracking. An effective composite process of "cryogenic aging - vibratory stress relief" involves keeping the sheet at -30°C for 2 hours, followed by 120 Hz high-frequency vibration. This promotes the dissipation of residual stress in the form of elastic waves, significantly reducing the peak residual stress from 180 MPa to 35 MPa.

05 On-Site Forming: Innovative Solutions for Developable Surfaces

For certain types of curved surfaces, on-site forming technology offers an innovative anti-cracking approach. Its core concept involves optimizing the design of complex non-developable surfaces into "developable surfaces" like cylinders or conical frustums, which can be bent on-site from flat sheets.

This technology has been successfully applied in projects like the Beijing New China International Exhibition Center Phase II.

Its advantage lies in completing the installation of all stiffeners and connectors on flat aluminum sheets in the factory before transporting them to the site for final bending and forming. This not only avoids the risk of damage to pre-formed curved panels during transportation but also reduces the need for repeated corrections due to springback or precision deviations, lowering the possibility of processing cracks from the source.

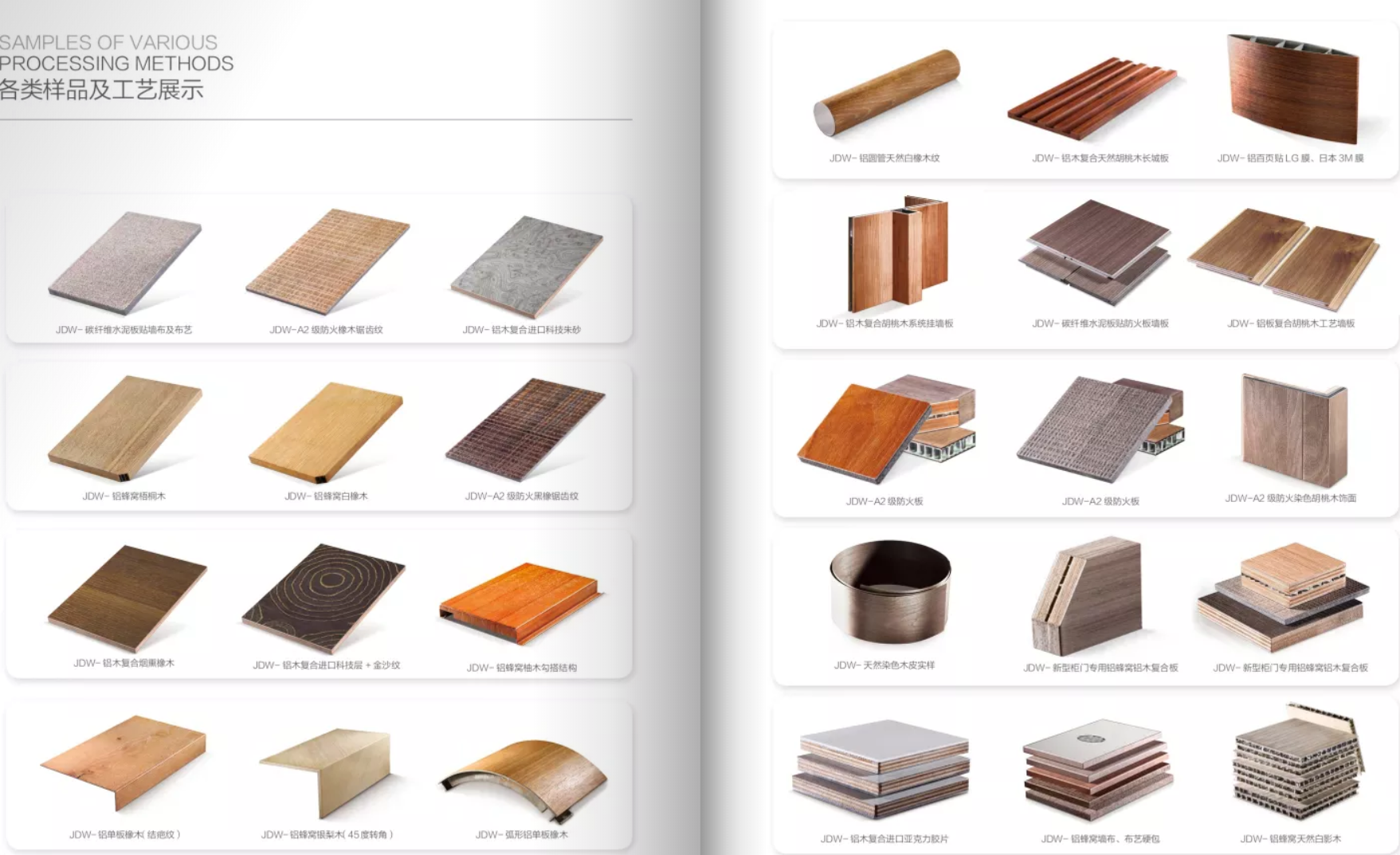

06 Structural Innovation: From Single Panels to Composite Systems

When the deformation capacity of a single-layer aluminum sheet reaches its limit, structural innovation provides new paths to prevent cracking.

The "Double-Curved Anodized Aluminum Panel Honeycomb Box" project, which won the Polaris Award, is a breakthrough. It employs a one-piece aluminum honeycomb composite structure, successfully overcoming the industry challenge of the anodized film on aluminum panels cracking and whitening when twisted due to high surface hardness. This is achieved through an original "bamboo-node-style force-bearing system."

This design not only achieves a crack-free surface effect for double-curved panels but also enhances overall strength through structural calculations. It ensures precision when multiple panels are spliced together, avoiding the need for expensive stretch-bent profiles.

At the process level, the application of pulsed argon arc welding technology significantly reduces cracking risks caused by the heat-affected zone (HAZ) of welds. By precisely controlling current pulses, the HAZ is reduced to within 3 mm. A weld seam 1 meter long can be completed in 30 segments, much like a surgeon performing precise work, effectively controlling welding stress and deformation.

Conclusion:

When a double-curved aluminum panel, refined through hundreds of computer simulations and 18 precise processing steps, finally reflects smooth light and shadow on a building, its value transcends that of an industrial product. Advanced structural innovations, such as one-piece aluminum honeycomb composite systems, are fundamentally changing the industry's rules. Their original force-bearing systems can even overcome the long-standing industry problem of high-hardness anodized aluminum panels cracking when twisted.

It is foreseeable that with the deep integration of digital control and intelligent monitoring technologies, the building envelopes of the future will no longer be passively defending against cracking but will become "smart skins" capable of real-time monitoring and early warning.