3 Critical Pre-Processing Steps for Wood Veneer Panels (That Most People Overlook)

Are you a fabricator or designer facing these issues with wood veneer panels?

Chipping & cracking during machining?

Finished surface not meeting expectations?

Warping or instability in the final product?

Often, the culprit isn't the machining itself, but inadequate pre-processing.

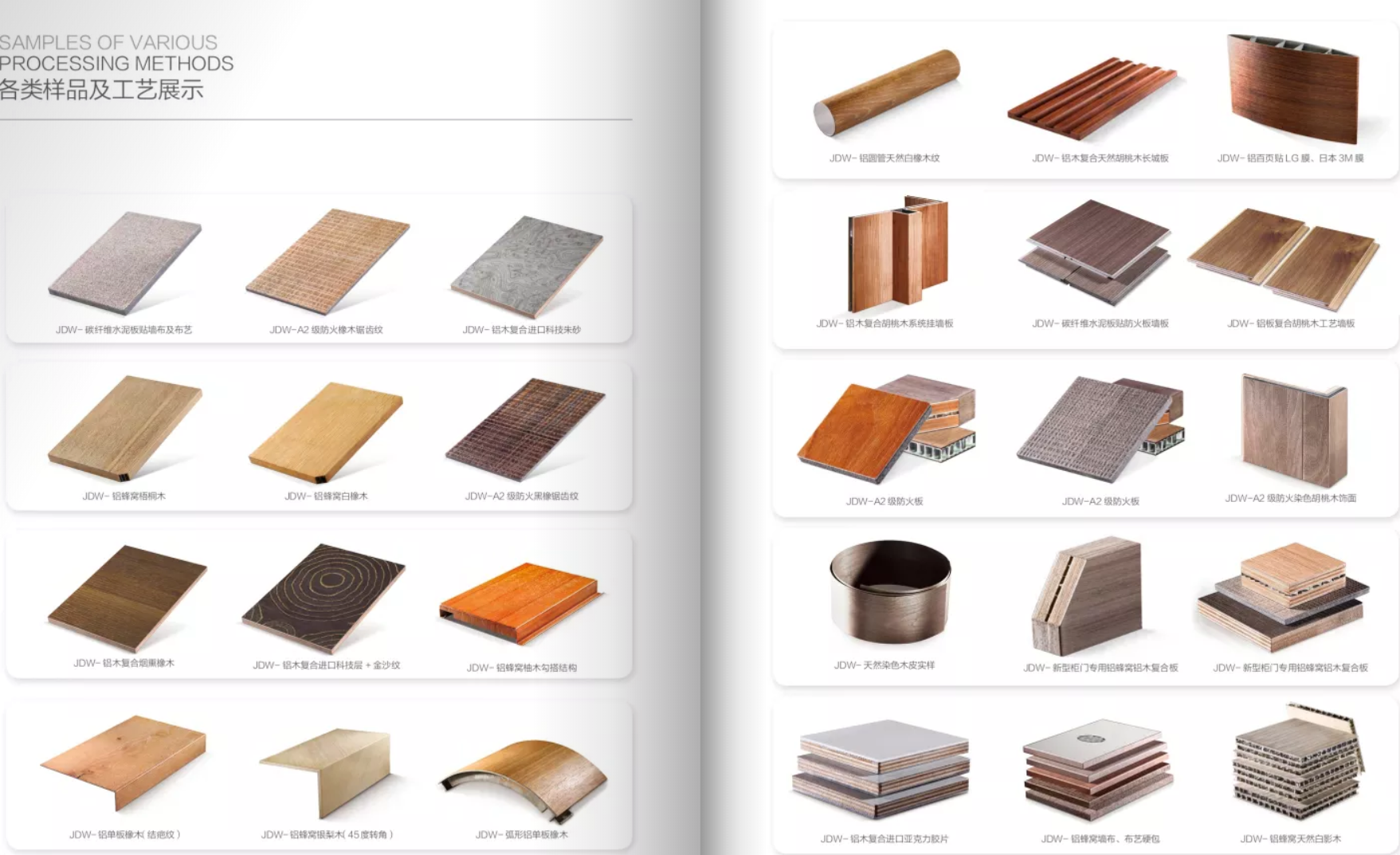

Before any premium wood veneer panel touches our machines, three non-negotiable steps ensure flawless results:

1. Proper Conditioning & Acclimation

Why? Wood is hygroscopic. Moving panels directly from a different climate into your workshop creates internal stress, leading to future warping.

Our Practice: We store all panels in a climate-controlled room (matching local RH/temperature) for 7-15 days minimum. This is the foundation for stability.

2. Digital Flaw Mapping & Layout Optimization

Why? Natural features like mineral streaks and knots can be liabilities or assets.

Our Practice: We use high-resolution scanning to create a digital "map" of each panel. This allows us to plan cuts strategically, maximizing yield and transforming natural characteristics into intentional design elements.

3. Customized Surface Pre-Treatment & Protection

Why? Dust, oils, or micro-scratches become glaringly obvious under final finishes.

Our Practice: A meticulous, dust-free cleaning followed by a tailored sealing or priming treatment based on the client's specified finish system. This guarantees a perfect canvas.

These steps don't appear on the final invoice, but they are our silent commitment to lower waste, higher efficiency, and stunning outcomes for our clients.

Pro Tip for You: Even without a climate-controlled room, let panels rest in your workshop for 24+ hours before machining. Always inspect and plan your layout visually—it prevents many basic issues.

A reliable supply chain is the backbone of your project.

If you're looking for high-end wood veneer panels that are pre-processed for stability and performance, or have a special project requiring technical collaboration…

DM me or comment “VENEER GUIDE” below, and I’ll send you our detailed Pre-Processing Checklist.

We can also arrange a quick 15-minute call to discuss your specific needs (hotel FF&E, custom furniture, commercial spaces) and provide free physical samples so you can see and feel the difference quality makes.