Why Woodgrain Aluminum Panels Are Becoming the New Standard for High-End Architectural Clacding

Today, in the pursuit of natural aesthetics and sustainable design, the warm texture of wood is always appealing. However, when we turn our focus to large-scale public buildings, commercial spaces, or façade projects with demanding durability requirements, the limitations of traditional solid wood become all too apparent—susceptibility to warping, high maintenance, fire safety concerns, and the increasingly critical issues of environmental impact and resource scarcity.

This is precisely why Woodgrain Aluminum Panels have emerged and are rapidly gaining popularity in the global architectural community. They are more than just a "wood-look" material; they represent a systematic solution that comprehensively surpasses solid wood in terms of performance, economics, and sustainability. Here are the five key reasons to consider:

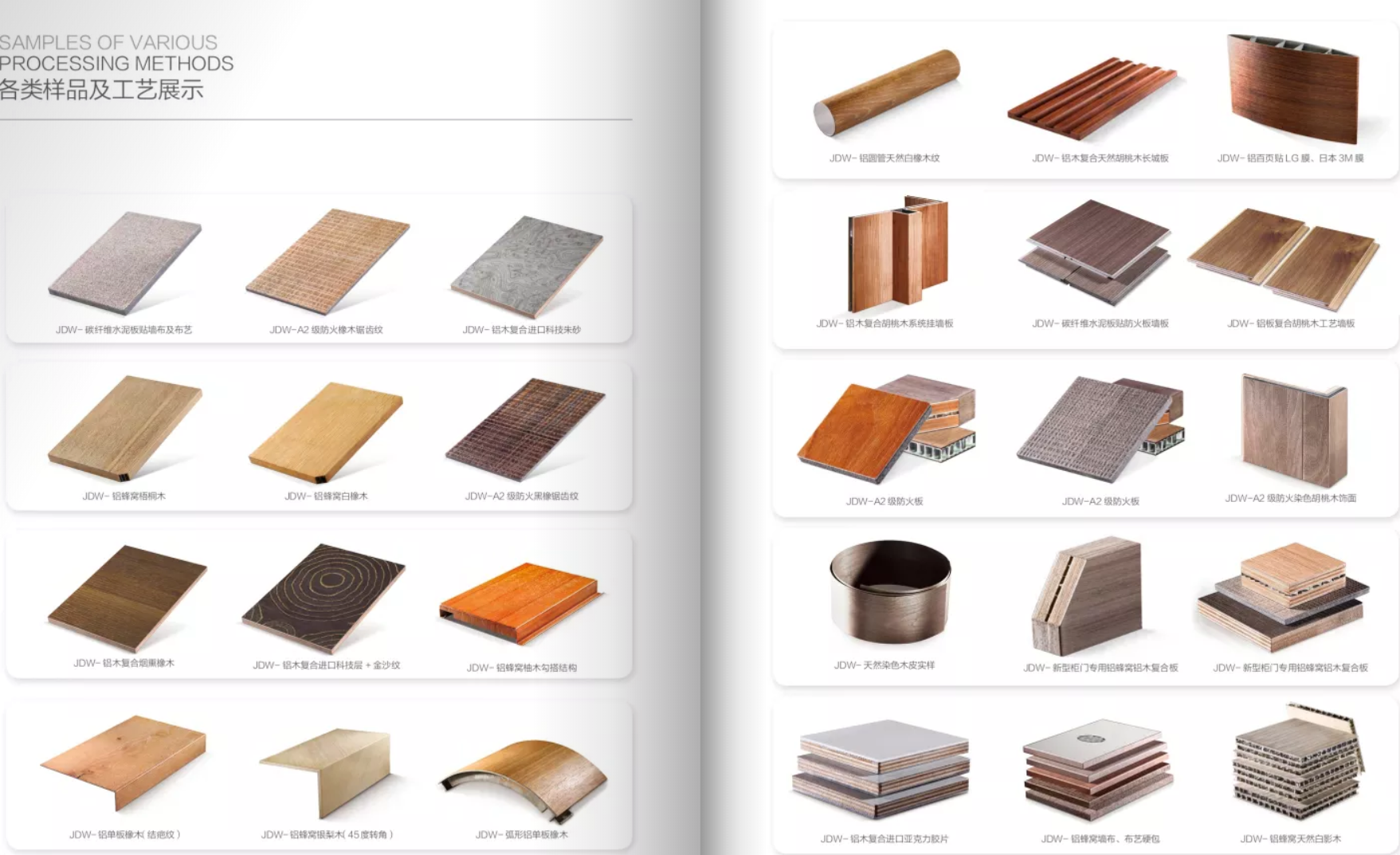

1. Superior Physical Performance: Armor for Buildings with a "Wooden" Look

Woodgrain aluminum panels are made from high-grade aluminum alloy, giving them unmatched hardness and strength compared to solid wood. Their tensile strength can reach 100-280 N/mm², yet they weigh only about one-third as much as solid wood of the same area, significantly reducing the building's structural load. More importantly, they completely overcome the inherent flaws of solid wood:

Extreme Weather Resistance: The surface is coated with PVDF fluorocarbon paint, which can withstand UV rays, acid rain, and temperature fluctuations, maintaining color and shape for 10-15 years. This solves the problem of solid wood cracking and fading outdoors.

Excellent Fire Resistance: The material meets China's Class A2 non-combustible standard, with a fire resistance temperature exceeding 600°C. This provides solid safety assurance, a critical performance that solid wood cannot match.

Anti-corrosion & Moisture-proof: Completely resistant to moisture, mold, and termites, making it perfect for high-humidity environments like swimming pools, canopies, and basements.

2. Eco-friendliness & Sustainability: Answering the Call of the Green Building Era

As forest resources become increasingly precious, sustainable design is a responsibility. Woodgrain aluminum panels are free of formaldehyde and any harmful gas emissions, ensuring healthy indoor air quality. Furthermore, the aluminum material is 100% recyclable with high residual value, perfectly aligning with circular economy principles. Choosing it means gaining the aesthetic appeal of wood while significantly reducing the need to harvest natural forests—a truly green choice.

3. Unlimited Design Possibilities: From "Limited by Material" to "In Control of Material"

The size and form of solid wood are constrained by the log itself, whereas woodgrain aluminum panels liberate designers' creativity.

Size Freedom: Can be produced in large panels up to 2000mm*6000mm, achieving a more holistic and grand visual impact that is "rarely achievable" with solid wood.

Versatile Forms: Can be easily fabricated into flat, curved, spherical, and even complex irregular shapes using advanced CNC bending technology.

Integrated Functionality: The hollow back can be filled with insulation, soundproofing, or acoustic materials, integrating decoration with building physics performance.

4. Cost-Effectiveness & Low Maintenance: A Better Lifecycle Cost

While the initial investment might be comparable to high-end solid wood, woodgrain aluminum panels are more economical over their entire lifecycle.

Efficient Installation: Factory prefabrication allows for modular on-site assembly, eliminating the need for cutting or painting on-site. This speeds up construction and saves significant labor and time costs.

Minimal Maintenance Cost: The fluorocarbon coating has excellent "self-cleaning" properties, making it difficult for pollutants to adhere. Routine cleaning often requires just rainwater rinsing or simple wiping to maintain its appearance. This avoids the expensive and cumbersome periodic maintenance of solid wood, such as sanding, refinishing, and preservative treatments.

5. Avoiding Market Pitfalls of Solid Wood, Ensuring Project Quality

The solid wood market has opacities, such as inferior products being passed off as superior ones, origin misrepresentation (e.g., passing off domestic birch as Russian birch), or engineered wood products being sold as solid wood. As an industrial product, woodgrain aluminum panels have clear standards and test reports for material, coating thickness, and color, ensuring stable and controllable quality. This saves project owners and designers the hassle of vetting materials and guarantees the perfect realization of the design vision.

Woodgrain aluminum panels are far more than a simple substitute; they are an upgrade for the future. They skillfully balance natural aesthetics, top-tier performance, sustainable responsibility, and project economics. From airports and hospitals to commercial complexes, from interior feature walls to stunning building façades, they are redefining the boundaries of "wooden" cladding with their undeniable advantages.

Are you working on a project seeking a decorative solution that is both beautiful, durable, and sustainable? Or perhaps you're interested in learning more about the technical specifications or application cases of woodgrain aluminum panels?

Feel free to start a discussion in the comments or send me a direct message. I am happy to share insights from our experience across various global projects and provide you with professional, objective material selection analysis and support.