Giving Simple Answers to Complex Designs: How 3D Technology "Translated" a Sydney Landmark

Views : 63

Update time : 2025-11-14 14:40:00

The renovated Sydney landmark, where 3D technology brought complex curves to life in metal.

During the renovation of a cultural landmark in Sydney, we faced a core challenge: how could we turn a design full of complex curves into a common language that everyone could accurately understand?

The answer was to let 3D technology become our "translator.

From "Individual Interpretation" to "Shared Vision"

A 3D model of the curved design—no more guesswork, only precise digital language.

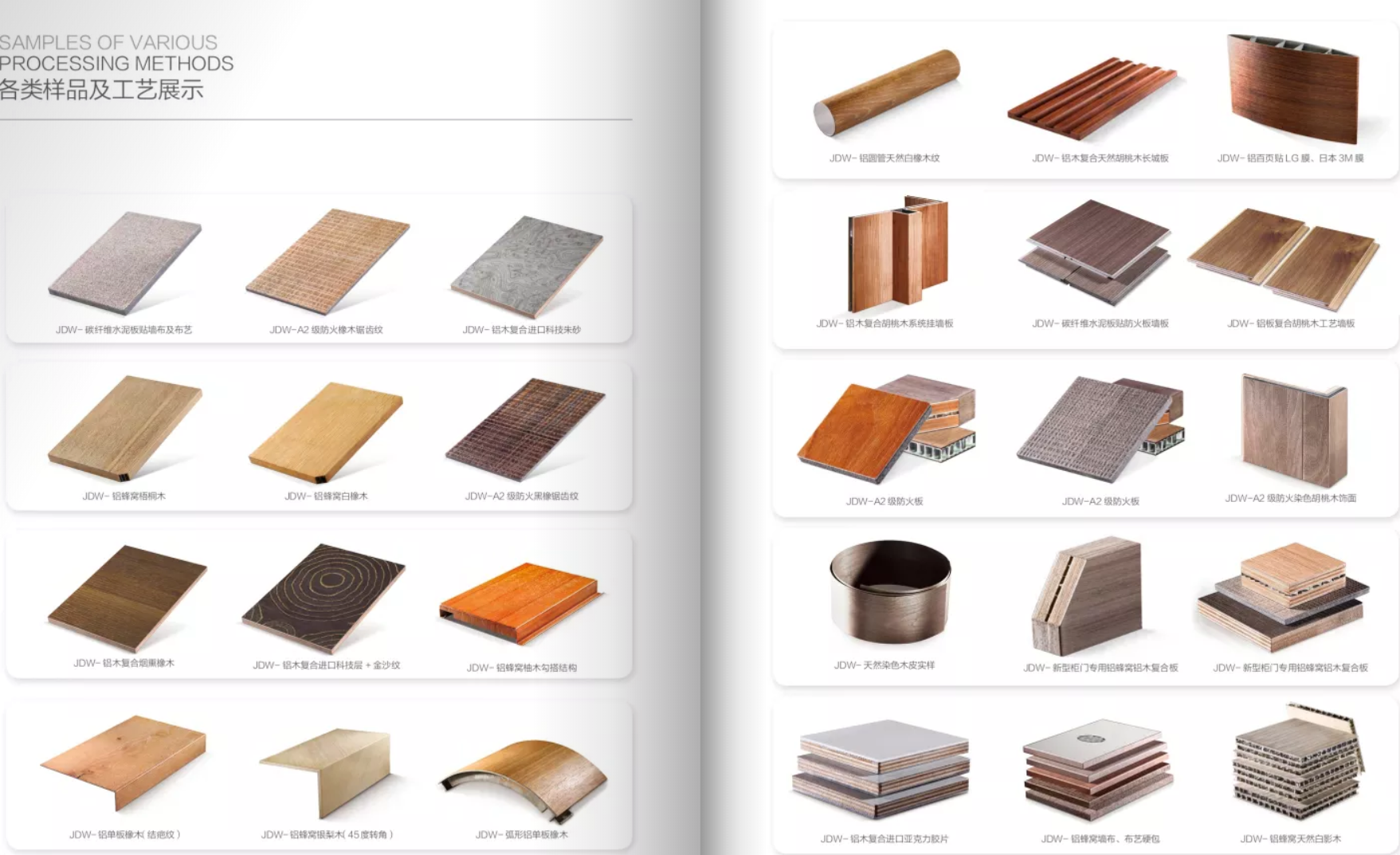

Traditional 2D drawings fall short when faced with complex curves. The high-precision 3D models we created became a "digital sandbox" for everyone. Before this, communication was like a game of broken telephone; afterwards, for the first time, architects, engineers, and our craftsmen stood in the same reality before the project even began.

HSG equipment translates 3D data into physical metal cuts, millimeter by millimeter.

From "Data Stream" to "Metal Flow"

Every panel in the workshop carries the "digital DNA" of the 3D model.

This model was far more than just a rendering. It became the source for production. Data flowed directly from the model to our processing equipment, guiding the machinery in millimeter-precise cutting and shaping. This not only significantly reduced material waste but also ensured that every meticulously crafted copper panel fit the building structure perfectly.

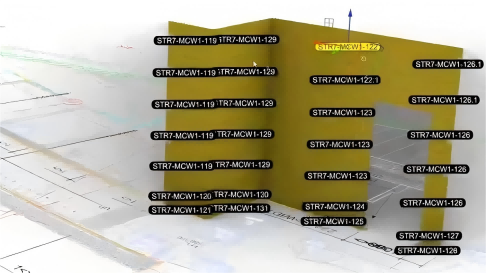

Model part numbers (e.g., STR7-MCW1-125) map directly to physical panel labels—zero distortion in translation.

From "Challenge" to "Badge of Honor"

3D previews let us solve problems here, before they became problems on site.

In the end, it was 3D technology that allowed us to preview all challenges in the virtual world, solving problems before they occurred. This enabled the bold design blueprint to be transformed, without loss, into the metallic reality now standing in the city.

This project solidified our belief: the best communication simplifies complexity, and the best production brings designs to life with precision.

相关新闻